E122

17.9.2010

Patent E122 - IP Portfolio A2

Pedal Feel Simulator Design And Diagnostics

Inventors: H. Leiber, V. Unterfrauner

2 Core Innovations

Patent E122 EN/ E122 US

Pedal Feel Simulator Design

Patent Status : Granted

Patent E122 DE1/E122 US1

Diagnostics of Feeding Valve and Pedal Feel Simulator

Patent Status : Granted

Patent E122DE-SA (DE112011102270)

Keyword: Pedal Feel Simulator Design

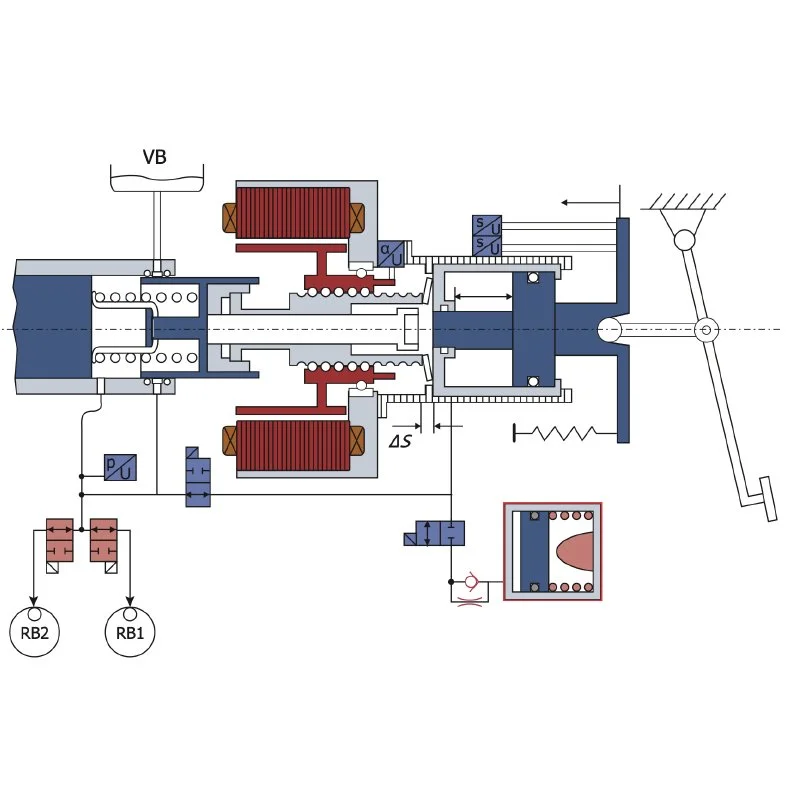

Actuating device for a vehicle brake system,with a first piston-cylinder unit (4), at least one working chamber of which is to be connected to at least one wheel brake of the vehicle via at least one hydraulic line,further comprising an electro-mechanical drive device and an actuating device (10, 5),wherein the actuating device has a further piston-cylinder unit (6, 41), the piston (6) of which can be actuated by means of the actuating device (10, 5) and which is connected to a piston of the first piston-cylinder unit (4) via a connecting devicecharacterized in that a displacement simulator (8) can be actuated by means of the further piston-cylinder unit (6, 41), which is connected to the further piston-cylinder unit (6, 41) via a hydraulic line (29) by means of a separating valve (22),wherein the further piston-cylinder unit (6, 41) is connected via a hydraulic line (29) and a connecting valve (30) to a further hydraulic line (28) which connects the first piston-cylinder unit (4) to the at least one wheel brake.

Claim Features

Abstract:

The actuating device for a vehicle brake system comprises two hydraulic piston-cylinder units, one of which actuates a travel simulator via the brake pedal The actuating device for a vehicle brake system comprises two hydraulic piston-cylinder units, the second of which actuates a travel simulator via the brake pedal and controllable valves and indirectly actuates the master cylinder unit, which is connected to the wheel brakes via controllable valves

Technical relevance

The innovation was not implemented in the described design of the master brake cylinder with a serial three-piston arrangement. In a further developed version of the technology (reference to patent family E132), a parallel arrangement of brake master cylinder and electromotive pressure supply unit with its own piston was pursued instead. However, the cost-efficient implementation of a pedal feel simulator is particularly relevant for future market applications, especially through the use of a non-linear return spring in combination with elastomer materials.

In addition, both the connection of the travel simulator to the pressure piston circuit, in this case the first piston-cylinder unit, and the integration of a so-called travel simulator in the closed brake circuit have proven to be advantageous and have established themselves on the market in 1-box brake systems. With a "travel simulator in the closed brake circuit" is meant a design in which the simulator is filled and emptied without hydraulic volume flow from the brake circuit - but solely by actuating or releasing the brake pedal.

Patent E122DE-TA (DE112011106127)

Keyword: Pedal Feel Simulator Diagnostics

Method for operating an actuating device of a brake system of a vehicle,wherein an electro-mechanical drive device (1) is used to drive a piston-cylinder unit (4) which is connected to at least one wheel brake via at least one switching valve (13) for supplying pressure medium,wherein pressure medium from a further piston-cylinder unit (6), the piston of which can be actuated by means of a pedal (10), can be supplied to a travel simulator (8),wherein pressure medium from the further piston-cylinder unit (6) can be fed to a brake circuit of the at least one wheel brake via a feed valve (30)characterized in that the method comprises a diagnostic step,wherein, for the diagnosis of the feed valve (30) when the switching valve (13) is closed and when the feed valve (30) is closed, a pressure build-up takes place by means of the electromechanical drive device (1) and the driven piston-cylinder unit (4) and the pressure increase is measured.

Claim Features

Abstract:

The method controls a brake system with a pedal-operated travel simulator and an electrically driven master cylinder, wherein a diagnostic step for checking the feed valve, which connects the working chamber of the second piston-cylinder unit to a brake circuit, is carried out by selective pressure build-up in the brake circuit with closed valves and subsequent pressure measurement.

Technical relevance

The innovation represents a central safety diagnostic procedure for modern brake systems that reliably checks the tightness of critical components such as the valve and travel simulator piston, even during operation - a key requirement for functional safety in brake-by-wire systems and automated driving.