E90

21.11.2005

Patent E90 - 1 - IP Portfolio A2

MUX ABS Control and Adaptive Pre-Pressure

Inventors: H. Leiber, Dr. T. Leiber

E90 - MUX ABS Control

8 Core Innovations

Patent E90EP

MUX ABS Control with Mapping-Based State Regulation Using Piston Position, Motor Current, and Pressure-Volume Profile

2 Claims

Patent Status : Granted

Patent E90DE

Further Essential Ideas of MUX ABS control

6 Claims

Patent Status : Granted

E90 - Adaptive Pre-Pressure

2 Core Innovations

Patent E90DE1

Adaptive upstream pressure control for low NVH

2 Claims

Patent Status : Granted

E90 - 1 MUX ABS Control

Patent E90EP (EP1874602)

CLAIM 1

Keywords: ABS MUX with Mapping-Based State Regulation Using Piston Position, Motor Current, and Pressure-Volume Profile

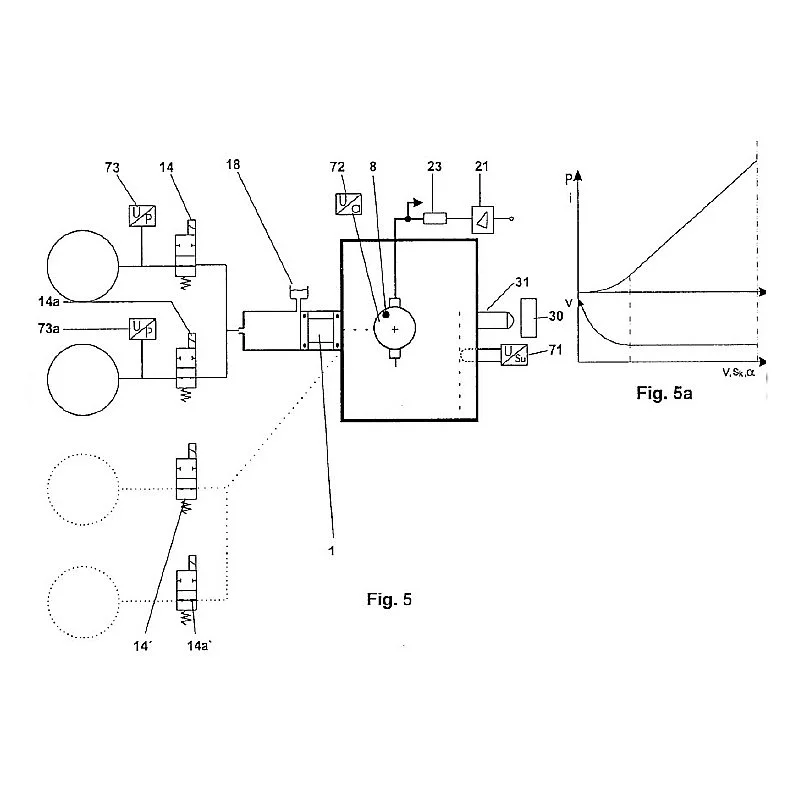

Brake system which has an actuating device (30), in particular a brake pedal, and a control and regulating device (22) which controls at least one electromotive drive device (8) on the basis of the movement and/or position of the actuating device (30),and the drive device (8) displaces a piston (1a) of a piston-cylinder system via a non-hydraulic transmission device,so that a pressure is established in the working chamber (4a', 4b') of the cylinder (4), the piston (1a) being arranged together with a hydraulically coupled further piston (1b) in a cylinder, i.e. tandem piston cylinder, and in that each working chamber (4a', 4b') of the tandem piston cylinder is connected to at least one wheel brake via at least one pressure line (13, 13a),wherein a valve (14, 14a, 15, 15a) is arranged between the brake cylinder of each wheel brake and a working chamber (4a', 4b') of the piston-cylinder system, and the control and regulating device (22) opens the valve (14, 14a, 15, 15a) to reduce or build up pressure in the brake cylinder and closes it to maintain the pressure in the brake cylinder,and in that the brake system has a pressure transmitter or a pressure sensor (73b) for detecting the pressure in one of two brake circuits or their pressure lines (13, 13a), in particular in the primary brake circuit,wherein the control and regulating device (22) regulates the pressure in one or more brake cylinders simultaneously or successively by means of the driven piston (1a) by means of the piston-cylinder system and the valves (14, 14a, 15, 15a) associated with the wheel brakes,characterized in that the piston-cylinder system is used both to build up and reduce the brake pressure for the brake booster and to implement the ABS and anti-slip control,and the control and regulating device regulates the pressure build-up and pressure reduction and the rate of change of the pressure build-up and pressure reduction in the wheel brakes as a function of the driving state or the brake control of the vehicle or of the respective wheel to be braked by means of the piston-cylinder system and by evaluating the pressure-volume characteristic of the wheel brakes via the piston travel, the current of the electric motor or the pressure determined by means of the pressure transmitter or pressure sensor (73b).

Claim Features

Abstract:

The invention relates to a brake system with a tandem-type piston-cylinder system which is actuated via an electric motor drive unit and non-hydraulic transmission and which both builds up and reduces the brake pressure in several wheel brakes with the aid of controllable valves, the control taking place on the basis of piston travel, motor current or pressure sensor values and taking into account the pressure-volume characteristics of the wheel brakes in order to realize ABS, ASR (Traction drive slip control) and brake booster functions depending on the driving state.

Technical Relevance:

Refer to the section below.

Patent E90EP (EP1874602)

CLAIM 7

Keywords: Adaptive Multi-Wheel Plunger Control with Dynamic Pressure Ramping

Method for adjusting a pressure in at least one brake cylinder of a brake system according to one of the preceding claims,characterized in that the pressure in one or more brake cylinders is optionally adjusted simultaneously or successively by means of the at least one piston-cylinder system and the valves assigned to the wheel brakes,wherein the rate of change of the pressure build-up and/or the pressure reduction in the wheel brakes is regulated by means of the piston-cylinder system as a function of the driving state or the brake control of the vehicle or of the respective wheel to be braked.

Claim Features

Abstract:

The method optionally regulates the brake pressure in several wheel brakes simultaneously or successively by means of a piston-cylinder system and associated valves, whereby the rate of pressure change is adapted dynamically depending on the driving condition or the brake control in order to enable pressure modulation for each wheel according to the situation.

Technical Relevance:

Refer to the section below.

Patent E90DE-SA (DE102005055751)

CLAIM 1

Keywords: Essentials of MUX ABS Control

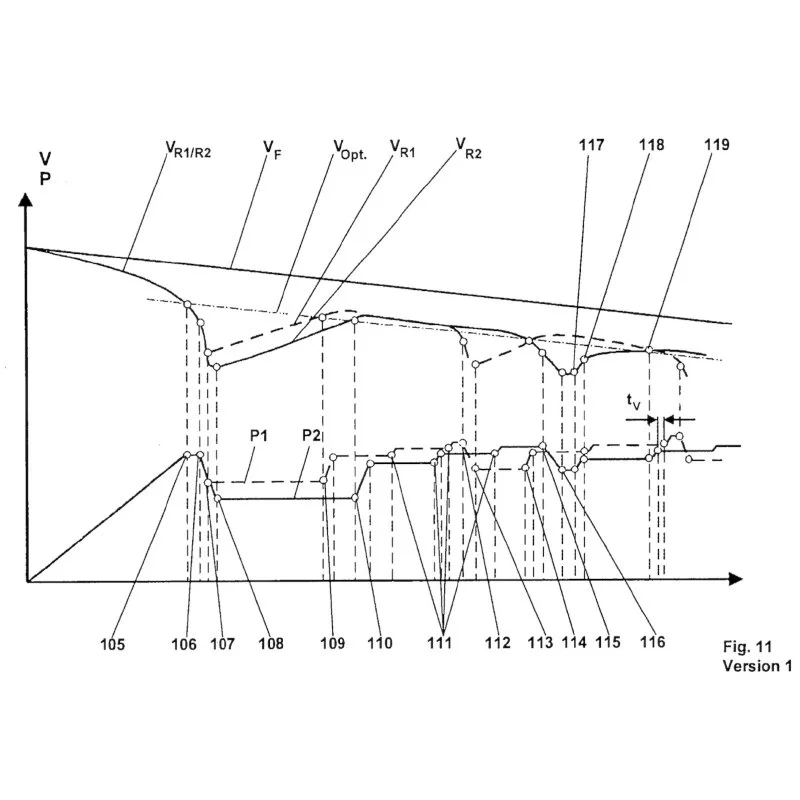

Brake system, having an actuating device and a control and regulating device, the control and regulating device controlling at least one electromotive drive device on the basis of the movement and/or position of the actuating device, wherein the electromotive drive device is a brushless motor which is controlled by output stages (21) via three lines from a microcontroller (22),wherein the drive device displaces a piston (1) of a piston-cylinder system via a non-hydraulic transmission device so that a pressure is established in a working chamber of the piston-cylinder system,wherein the working chamber is connected to a wheel brake via a pressure line, wherein at least one valve is arranged between a brake cylinder of the wheel brake and the working chamber of the piston-cylinder system, wherein the control and regulating device opens the at least one valve to reduce or build up pressure in the brake cylinder,characterized in that the control and regulating device regulates the pressure change in the wheel brakes by evaluating the pressure-volume characteristic of the corresponding wheel brakes over the piston travel,wherein the piston-cylinder system generates a brake pressure build-up and brake pressure reduction to realize ABS control, and wherein the piston travel is recorded via a rotation angle sensor and a corresponding counter,wherein the control and regulating device regulates the pressure reduction or pressure build-up and the rate of change of the pressure reductionand/or pressure build-up in the wheel brakes as a function of the driving state or the brake control of the vehicle or of the respective wheel to be braked by means of the position of the piston of the piston-cylinder system,wherein the rate of change of the pressure has a constant gradient and the pressure gradient is adjusted by a variably controlled electromotive piston drive.

Claim Features

Abstract:

The patent describes an electro-hydraulic brake system with brushless motor and non-hydraulic transmission, in which a microcontroller precisely regulates the piston travel in order to enable a defined pressure build-up and reduction with constant pressure gradient in the wheel brakes via a control derived from piston travel and pressure volume characteristic curve, including ABS functionality and driving state adaptation.

Technical Relevance:

Refer to the section below.

Patent E90DE-SA (DE102005055751)

CLAIM 2

Keywords: Essentials of MUX ABS Control

Brake system, having an actuating device and a control and regulating device, the control and regulating device controlling at least one electromotive drive device on the basis of the movement and/or position of the actuating device,wherein the electromotive drive device is a brushless motor which is controlled by output stages (21) via three lines from a microcontroller (22),wherein the drive device displaces a piston (1) of a piston-cylinder system via a non-hydraulic transmission device so that a pressure is established in a working chamber of the piston-cylinder system,the working chamber being connected to a wheel brake via a pressure line,wherein at least one valve is arranged between a brake cylinder of the wheel brake and the working chamber of the piston-cylinder system,wherein the control and regulating device opens the at least one valve to reduce or build up pressure in the brake cylinder, characterized in that the control and regulating device regulates the pressure change in the wheel brakes by evaluating the pressure-volume characteristic curve of the corresponding wheel brakes over the piston travel, the piston-cylinder system performing a brake pressure build-up and brake pressure reduction.The piston-cylinder system generates a brake pressure build-up and brake pressure reduction to realize ABS control, and the piston travel is recorded via a rotation angle sensor and a corresponding counter,whereby during commissioning and also during operation of the brake system, a characteristic map is created in which the position of the piston is assigned to different current intensities, the control and regulating device adapting the characteristic map if the position and motor torque do not match.

Claim Features

Abstract:

The patent describes an electromechanical brake system with brushless motor and non-hydraulic transmission, in which the brake pressure is precisely controlled via an adaptive current-piston position map, and in which ABS functions are realized by controlled pressure build-up and reduction by means of pressure-volume characteristics of the wheel brakes.

Technical Relevance:

Refer to the section below.

Patent E90DE-SA (DE102005055751)

CLAIM 3

Keywords: Essentials of MUX ABS Control

Brake system, comprising an actuating device and a control and regulating device,wherein the control and regulating device controls at least one electromotive drive device on the basis of the movement and/or position of the actuating device,wherein the drive device displaces a piston (1) of a piston-cylinder system via a non-hydraulic transmission device so that a pressure is established in a working chamber of the piston-cylinder system, the working chamber being connected to a wheel brake via a pressure line,wherein at least one valve is arranged between a brake cylinder of the wheel brake and the working chamber of the piston-cylinder system,wherein the control and regulating device opens the at least one valve to reduce or build up pressure in the brake cylinder,characterized in that the control and regulating device regulates the pressure change in the wheel brakes by evaluating the pressure-volumecharacteristic of the corresponding wheel brakes via the piston travel,wherein the piston travel is detected via a rotation angle sensor and the rotation angle sensor is used together with pressure sensors in the wheel circuits to control the piston, andwherein the speed of the piston is controlled for constant pressure gradient control by means of the pressure volume characteristic curve.

Claim Features

Abstract:

The patent describes an electromechanical brake system in which a piston is moved by an electric motor via a non-hydraulic transmission, wherein the pressure control in the wheel brakes is carried out via a piston travel and pressure sensor-based evaluation of the pressure-volume characteristics of the wheel brakes and the piston speed is controlled to generate a constant pressure gradient.

Technical Relevance:

Refer to the section below.

Patent E90DE-SA (DE102005055751)

CLAIM 4

Keywords: Essentials of MUX ABS Control

Method for setting a pressure in at least one brake cylinder of a brake system which has an actuating device and a control and regulating device,wherein the control and regulating device controls at least one electromotive drive device on the basis of the movement and/or position of the actuating device,wherein the electromotive drive device is a brushless motor which is controlled by output stages (21) via three lines from a microcontroller (22),wherein the drive device displaces a piston of a piston-cylinder system via a non-hydraulic transmission device, so that a pressure is established in the working chamber of the cylinder,wherein the working chamber is connected to a wheel brake via a pressure line,wherein a valve is arranged between the brake cylinder of the wheel brake and the working chamber of the piston-cylinder system,wherein the control and regulating device opens the valve for pressure build-up and/or pressure reduction in the brake cylinder,characterized in that the control and regulating device regulates the pressure build-up and/or pressure reduction and the rate of change of the pressure build-up and/or pressure reduction in the wheel brakes as a function of the driving state or the brake control of the vehicle or of the respective wheel to be braked by means of the position of the piston of the piston-cylinder system and by evaluating the pressure-volume characteristic of the wheel brakes via the piston travel,wherein the piston travel is recorded via a rotation angle sensor and a corresponding counter,wherein the control and regulating device simultaneously or successively regulates the pressure in one or more brake cylinders by means of the at least one piston-cylinder system and the valves assigned to the wheel brakes,wherein the piston-cylinder system generates a brake pressure build-up and brake pressure reduction to realize an ABS control,wherein the pressure reduction or pressure build-up and the rate of change of the pressure reduction and/or pressure build-up in the wheel brakes are regulated as a function of the driving condition or the brake control of the vehicle or the respective wheel to be braked by means of the position of the piston of the piston-cylinder system,wherein the rate of change of the pressure has a constant gradient and the pressure gradient is adjusted by a variably controlled electromotive piston drive.

Claim Features

Abstract:

The patent describes a method for pressure control in vehicle brakes, in which a variably controlled brushless electric motor moves a piston via a non-hydraulic transmission, whereby the control generates a constant pressure gradient based on the piston travel and the pressure-volume characteristics of the wheel brakes in order to precisely implement ABS functions and a driving condition-dependent brake force distribution.

Technical Relevance:

Refer to the section below.

Patent E90DE-SA (DE102005055751)

CLAIM 5

Keywords: Essentials of MUX ABS Control

Method for adjusting a pressure in at least one brake cylinder of a brake system, which has an actuating device and a control and regulating device,wherein the control and regulating device controls at least one electromotive drive device on the basis of the movement and/or position of the actuating device,wherein the electromotive drive device is a brushless motor which is controlled by output stages (21) via three lines from a microcontroller (22),wherein the drive device displaces a piston of a piston-cylinder system via a non-hydraulic transmission device, so that a pressure is established in the working chamber of the cylinder, the working chamber being connected to a wheel brake via a pressure line,wherein a valve is arranged between the brake cylinder of the wheel brake and the working chamber of the piston-cylinder system,wherein the control and regulating device opens the valve for pressure build-up and/or pressure reduction in the brake cylinder, characterized in that the control and regulating device regulates the pressure build-up and/or pressure reduction and the rate of change of the pressure build-up and/or pressure reduction in the wheel brakes as a function of the driving state or the brake control of the vehicle or of the respective wheel to be braked by means of the position of the piston of the piston-cylinder system and by evaluating the pressure-volume characteristic of the wheel brakes via the piston travel,whereby the piston travel is recorded via a rotary angle sensor and a corresponding counter,wherein the control and regulating device simultaneously or successively regulates the pressure in one or more brake cylinders by means of the at least one piston-cylinder system and the valves assigned to the wheel brakes,wherein the piston-cylinder system generates a brake pressure build-up and brake pressure reduction for the realization of an ABS control,wherein a characteristic map is applied during commissioning and also during operation of the brake system, in which the position of the piston is assigned to different current intensities,wherein the control and regulating device adapts the characteristic map if the position and motor torque do not match.

Claim Features

Abstract:

The patent describes a method for driving-state-dependent pressure control in vehicle brakes, in which a brushless motor moves a piston via a non-hydraulic gearbox, the position and motor torque of which is monitored and adapted by means of an adaptive current-position map, and in order to control via valves a precise pressure build-up and reduction with a constant pressure gradient for ABS functions in one or more wheel brake cylinders by evaluating the pressure-volume characteristics of the wheel brakes.

Technical Relevance

Refer to the section below.

Patent E90DE-SA (DE102005055751)

CLAIM 6

Keywords: Essentials of MUX ABS Control

Method for adjusting a pressure in at least one brake cylinder of a brake system which has an actuating device and a control and regulating device,wherein the control and regulating device controls at least one electromotive drive device on the basis of the movement and/or position of the actuating device,wherein the drive device displaces a piston of a piston-cylinder system via a non-hydraulic transmission device so that a pressure is established in the working chamber of the cylinder,wherein the working chamber is connected to a wheel brake via a pressure line,wherein a valve is arranged between the brake cylinder of the wheel brake and the working chamber of the piston-cylinder system,wherein the control and regulating device opens the valve for pressure build-up and/or pressure reduction in the brake cylinder,characterized in that the control and regulating device regulates the pressure build-up and/or pressure reduction and the rate of change of the pressure build-up and/or pressure reduction in the wheel brakes as a function of the driving state or the brake control of the vehicle or of the respective wheel to be braked by means of the position of the piston of the piston-cylinder system and by evaluating the pressure-volume characteristic of the wheel brakes via the piston travel,wherein the piston travel is detected via a rotation angle sensor and the rotation angle sensor is used together with pressure sensors in the wheel circuits to control the piston,wherein the control and regulating device simultaneously or successively regulates the pressure in one or more brake cylinders by means of the at least one piston-cylinder system and the valves assigned to the wheel brakes,whereby a speed control of the piston for a constant pressure gradient control takes place by means of the pressure volume characteristic curve.

Claim Features

Abstract:

The patent describes a method for precise brake pressure control in wheel brakes, in which a piston is moved by an electric motor drive unit via a non-hydraulic transmission, whereby the control - based on piston travel, pressure sensors and the pressure-volume characteristics of the wheel brakes - enables constant pressure gradient control, which is applied to several brake cylinders depending on the driving condition for ABS and brake control functions.

Technical Relevance

Refer to the section below.

Technical Relevance of the MUX ABS Patents

E87EP (EP1907253), E90EP (EP1874602), E90DE (DE102005055751)

The above-mentioned patents formed the basis for the development of a new type of ABS prototype with pressure control in the closed brake circuit using so-called hydraulic multiplex operation. This process enabled impressively short braking distances on roads with low coefficients of friction - especially on ice and snow, and on µ-split roads.

However, multiplex control reached its limits at higher coefficients of friction, for example on asphalt: In addition to physical challenges caused by the larger pressure jumps and time delays of hydraulic multiplexing, NVH problems (noise and vibrations) also arose, particularly when pressure was reduced simultaneously in several wheel brakes with different pressure levels. This resulted in equalizing flows between the wheel brake cylinders within the closed system, which had a negative control and acoustic impact and impaired ride comfort.

Another obstacle to the series launch was the increased dynamic requirement for the electric motor, which was necessary in multiplex operation in order to reliably implement rapid pressure changes. These requirements could not be met by the electric motors available on the market at the time of early development. A new type of motor was therefore required - in particular a DAG motor - which was initially not in the portfolio of common motor manufacturers. The associated investments in development and industrialization increased the system costs and slowed down economic implementation. However, a separate study by BMW AG showed that the unit costs of the DAG motor in series production were competitive and not disadvantageous compared to conventional solutions.

Despite the lack of market penetration, the concept of the closed brake circuit - especially for 2-channel pressure actuators for a vehicle axle - continues to have a high technological relevance. Thanks to the model-based clarity and physical predictability of such systems, new potential for automation and control quality is opening up, especially in conjunction with artificial intelligence and model-predictive control algorithms.

21.11.2005

Patent E90 - 2 - IP Portfolio A2

E90 - 2 Adaptive Pre-Pressure

Inventors: H.Leiber, Dr. T. Leiber

Patent E90DE-TA1 (DE102005063658)

Claim 1

Keywords: Adaptive Pre-Pressure Control for Low NVH

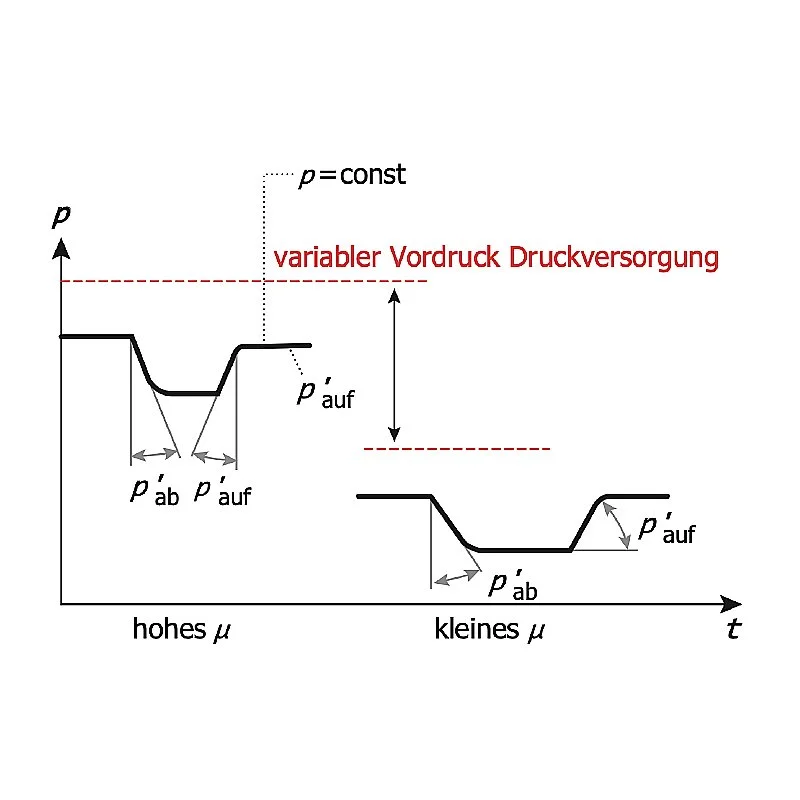

Brake system, an actuating device and a control and regulating device,Brake system, comprising an actuating device and a control and regulating device,wherein the control and regulating device controls at least one electromotive drive device (8) on the basis of the movement and/or position of the actuating device, wherein the drive device displaces a piston (1) of a piston-cylinder system via a non-hydraulic transmission device (5a), so that a pressure is established in a working chamber of the piston-cylinder system, the working chamber being connected to at least one wheel brake (15, 17) via a pressure line (13)characterized in that at least one valve (14, 14a, 14', 14a', 16, 16a) is arranged between a brake cylinder of the at least one wheel brake (15, 17) and the working chamber of the piston-cylinder system, the control and regulating device opening the at least one valve (14, 14a, 14', 14a', 16, 16a) to build up pressure in the brake cylinder and closing it to hold the pressure in the brake cylinder,wherein the pressure in one or more brake cylinders is regulated simultaneously or successively by means of the piston-cylinder system and the at least one valve (14, 14a, 14', 14a', 16, 16a),wherein during the regulation by means of the piston-cylinder system, an initial pressure is regulated, wherein the control and regulating device is designed to set a first initial pressure (91) in the case of a high coefficient of friction and to set a second initial pressure (91a) in the case of a low coefficient of friction, wherein the first initial pressure (91) is significantly higher than the second initial pressure (91a).

Claim Features

Abstract:

The invention relates to an electro-hydraulic brake system in which an electric motor actuates a piston via a non-hydraulic transmission in order to generate pressure in the working chamber, which pressure is regulated and transmitted to the brake cylinders via valves in a wheel-selective manner, where an adaptable upstream pressure is being set depending on the coefficient of friction of the road surface in order to enable optimized brake pressure regulation.

Technical relevance

The innovation enables noise-optimized ABS control by adjusting the brake upstream pressure depending on the coefficient of friction of the road and in line with requirements. This reduces valve activity and pressure fluctuations, resulting in noticeably quieter and more comfortable braking behavior, especially in electric vehicles and premium vehicles. This is particularly important for 1-box brake systems that are installed on the fire wall of the vehicle. It also reduces the mechanical load on the brake system by reducing the pressure vibrations caused by pressure modulation.

Patent E90DE-TA1 (DE102005063658)

Claim 13

Keywords: Adaptive Pre-Pressure Control for Low NVH

Method for adjusting a pressure in at least one brake cylinder of a brake system by means of a control and regulating device, wherein the control and regulating device controls at least one electromotive drive device (8) on the basis of the movement and/or position of the actuating device,wherein the drive device adjusts a piston (1) of a piston-cylinder system in such a way that a pressure is established in a working chamber of the piston-cylinder system,the working chamber being connected to at least one wheel brake (15, 17) via a pressure line, and characterized in that at least one valve (14, 14a, 14', 14a', 16, 16a) is arranged between a brake cylinder of the at least one wheel brake (15, 17) and the working chamber of the piston-cylinder system,wherein the control and regulating device opens the at least one valve (14, 14a, 14', 14a', 16, 16a) to build up pressure in the brake cylinder and closes it to maintain the pressure in the brake cylinder,wherein the pressure in one or more brake cylinders is adjusted simultaneously or successively by means of the at least one valve (14, 14a, 14', 14a', 16, 16a),wherein a first pre-pressure (91) is set when the coefficient of friction is high and a second pre-pressure (91a) is set when the coefficient of friction is low, wherein the first pre-pressure (91) is significantly higher than the second pre-pressure (91a).

Claim Features

Abstract:

The invention relates to a method for electro-hydraulic brake systems in which an electric motor actuates a piston via a non-hydraulic transmission in order to generate pressure in the working chamber, which pressure is regulated and transmitted to the brake cylinders via valves in a wheel-selective manner , wherein an adaptable

upsteam pressure is set depending on the coefficient of friction of the road surface in order to enable optimized brake pressure regulation.

Technical relevance

ThThe innovation enables noise-optimized ABS control by adjusting the brake upstream pressure depending on the coefficient of friction and in line with requirements. This reduces valve activity and pressure fluctuations, resulting in noticeably quieter and more comfortable braking behavior, especially in electric vehicles and premium vehicles. This is particularly important for 1-box brake systems that are installed on the fire wall of the vehicle. It also reduces the mechanical load on the brake system by reducing the pressure vibrations caused by pressure modulation.